Best Welding Rod Oven Used

Nowadays, there are so many products of welding rod oven used in the market and you are wondering to choose a best one. You have searched for welding rod oven used in many merchants, compared about products prices & reviews before deciding to buy them.

You are in RIGHT PLACE.

Here are some of best sellings welding rod oven used which we would like to recommend with high customer review ratings to guide you on quality & popularity of each items.

SÜA – Portable Electrode Drying Oven – 22 Lbs (10 Kg) TRC Series – 115 Volts

- The TRC Series is a lightweight portable electrode drying oven that prevents electrodes from absorbing moisture that can negatively affect the welding job.

- Two models available, TRC-5 can store up to 11 Lbs (5 Kg) and TRC-10 can store 22 Lbs (10 Kg) of 18 inches long electrodes or smaller – Easy to lift electrodes basket that can be locked open for convenient one-hand operation even with the thickest welding gloves.

- Temperature range: Ambient – 302 °F (Ambient – 150 °C) when connected at 115 Volts – Easy to set-up analog temperature dial. ***For Model TRC-10 only

- higher temperatures, (570 °F – 300 °C) can be reached when connected at 220 Volts***

- Weight empty: 9.5 Lb – Height: 24″ – Diameter of Cylinder: 6-½” – Inlet Power: 115V / 220V

- Can be used at the shop or in the field. Compatible with generators/welders with 115 Volts three plug outlets. A must-have when welding E7018, E7024, and other Low Hydrogen electrodes

Stick electrodes must be properly stored in order keep its quality weld deposition. When stick electrodes absorb moisture from the air, they must be dried to restore their ability to deposit quality welds. Electrodes with too much humidity may results in welds with cracking or porosity. Operational characteristics may be affected as well. If you’ve noticed unexplained weld cracking or porosity problems, or if the stick electrode arc performance is not at its best, it may be due to the presence of moisture in the electrode coating. Proper storage methods or re-drying procedures must be applied. Low Hydrogen Electrodes like the commonly used E7018 must be dry to perform adequately, once the original package has been opened, they must be stored in an electrode oven at 250F – 300F. AWS D1.1 Structural Welding Code specifies allowable atmospheric exposure of 4 hours for this type of electrodes. After that time, low hydrogen electrodes must be re-dried. Non-Low Hydrogen Electrodes can also be affected by moisture. If they are exposed to humid air for long periods of time the welding characteristics may be affected. It is recommended to store the electrodes in a heated oven at 100F – 120F.

Lincoln Electric Hydroguard Portable Electrode Oven| 10 lb Capacity | Premium Fiberglass Insulation | 115 V Only | K2932-1

- Moisture protection – used to prevent moisture from contaminating your welding electrodes and to maintain low hydrogen weld deposit properties. Moisture is a common cause of weld cracking or Porosity.

- Portable design – easy to transport, metal case rod oven weighs 10.5 lbs.

- 10 lb capacity – designed to allow storage of up to 10 pounds of 18” or smaller electrodes.

- Preset & insulated temperature – the oven chamber is preset to 300° f and features 1.5” wall insulation to efficiently maintain the desired thermal properties.

- Rod elevator – the oven chamber has a lift removable storage rack which makes it easy to extract your stored electrodes.

- Built to last – durable steel construction & tough powder-coat finish.

- Versatility – perfect for use at home, on a farm, in the shop, in maintenance, in construction or in general fabrication.

- Made in the usa and features a 1 year warranty

Outstanding moisture resistance for improved weld quality hydro guard rod ovens from Lincoln Electric help you protect your stick electrodes from moisture pickup, a major contributor to weld cracking and porosity. Protect your rods and drive moisture away. Your welds depend on it.

Forney 30705 E7018 Welding Rod, 3/32-Inch, 5-Pound

- The product is 5LB 3/32″ 7018 Weld Rod

- Easy to use

- All position welding, low hydrogen rod for general purpose AC applications requiring low penetration, can also be used on DC+

- Designed for welding head enable steels and projects involving hard to weld steels including thick sections and restrained joints with cracking issues

- Not recommended for use with low open circuit-Voltage OCV power sources

- Excellent for tack welds and out of position welding

- Ideal for general fabrication of cold roll steels

5 lb., 3/32″, 7018 welding Rod. E7018 mild steel “low hydrogen” Welding electrodes easily produces quality results on smaller Amperage DC or higher amperage AC welders. It is suitable for all positions on hard enable steels where no preheat is used, and on cold rolled steels normally exhibiting excessive porosity when Welded and conventional rod. The low hydrogen content reduces cracking and peeling of the weld material. Use for field erections, steel structures, frames, Trailer hitches and chassis. Recommended Polarity: DCEP (reverse)or AC. Diameter (inches): 3/32″ Weight lbs.: 5 tensile strength (PSI): 84, 000 amperage: 65-100 made in the USA. E7018 mild steel “low hydrogen” Welding Rod 5# Package Made in the USA

Keen KT-15 W/T Holding Portable Welding Rod Oven (120V/240V) – Maintains up to 15 lbs (6.8 kg.) of 18" (45.7 cm) electrodes at optimum temperature.

- Stores 15 lbs. of flux-coated 7018 low-hydrogen SMAW welding rods up to 18 inches long to prevent weld defects

- Economical portable welding rod storage oven keeps hygroscopic low-hydrogen welding electrodes dry in the field

- Portable, lightweight design provides protection for welding rods during transfer from the shop holding oven to the field

- Exceeds AWS D1.1 Structural Welding Code mandatory guidelines for heated welding rod storage

- Stable, square-shaped portable welding rod oven design with rod lifter for easy removal of welding rods in the field

Made in USA – CSA-listed

About the KT-15W/T Portable Rod Oven – 15 lbs. Capacity

The KT-15W/T is designed to store 15 lbs. of welding electrodes during transfer from large shop ovens and at the job location. Economical, lightweight and easy to carry, our KT-15W/T model maintain rods at ideal temperatures to prevent moisture pick-up and to optimize welds.

The KT-15’W/T’s small capacity is suitable for the hobby welder as well as the highly trained professional. It out-performs most portable ovens on the market and has a solid steel construction for long product life and durability.

Heavy-Duty Construction

The KT-15W/T has a solid steel construction for long product life and durability. The exterior is powder-coated in KEEN blue and features a rugged handle for carrying the unit. 1″ (2.54 cm) Thermal insulating wool makes oven energy- efficient and keeps electrodes hot and moisture-free.

The KT-15W/T features a liftable “rod elevator” with handle that supports and lifts the rods. An exterior, red “ON” indicating light is standard. The KT-15W/T welding rod oven features an external dial-adjustable thermostat with a range of 150-300F.

Performance Heating.

The custom-designed heating elements used on our portable ovens are part of a new class of highly energy-efficient, technologically-advanced heating elements that have a very low environmental impact. They reach maximum operating temperature in just 5-10 seconds and have a very low amperage draw enabling the oven to be extremely energy-efficient in the field.

Quality Temperature Control and Electrical Safety

Because of our unique self-regulating heating technology, thermostats are not a necessary safety feature for our portable ovens. The only case in which they would be necessary is if the user wants to reduce the temperature below 250°F for storing electrodes that require lower temperatures than low-hy rods.

Keen KT-15EC Portable Welding Rod Holding Oven – 120V/240V – 15 lbs. Capacity – with Lid Latch and On/Off Light – Special Economy Version (No Rod Lifter)

- Stores 15 lbs. of flux-coated 7018 low-hydrogen SMAW welding rods up to 18 inches long to prevent weld defects

- Economical portable welding rod storage oven keeps hygroscopic low-hydrogen welding electrodes dry in the field

- Portable, lightweight design provides protection for welding rods during transfer from the shop holding oven to the field

- Exceeds AWS D1.1 Structural Welding Code mandatory guidelines for heated welding rod storage

- Stable, square-shaped portable welding rod oven design for easy removal of welding rods in the field, hinged lid with draw pull catch, exterior ON/OFF indicator light and more

Made in USA

Avoid weld defects like wormholes and longitudinal cracking by keeping your low-hydrogen rods hot and dry in the field. The Keen KT-15EC portable welding oven provides heated welding rod storage to prevent moisture absorption in the flux coating. Maintains factory-fresh dryness for 15 lbs. of 18″ SMAW low-hydrogen stick electrodes

About the KT-15EC Portable Rod Oven – 15 lbs. Capacity

The KT-15EC is designed to store 15 lbs. of welding electrodes during transfer from large shop ovens and at the job location. Economical, lightweight and easy to carry, our KT-15EC model maintain rods at ideal temperatures to prevent moisture pick-up and to optimize welds.

The KT-15EC’s small capacity is suitable for the hobby welder as well as the highly trained professional. It out-performs most portable ovens on the market and has a solid steel construction for long product life and durability. It’s low cost and compact size enables shops to keep 10 or 20 on hand for welders heading out to the field.

Heavy-Duty Construction

The KT-15 has a solid steel construction for long product life and durability. The exterior is powder-coated in KEEN blue and features a rugged handle for carrying the unit. 1″ (2.54 cm) Thermal insulating wool makes oven energy-efficient and keeps electrodes hot and moisture-free. The KT-15EC design features a round inner chamber with a square exterior to provide stability while standing in an upright position. The KT-15EC portable welding electrode oven features a locking latch for the sturdy hinged lid. A red “ON” indicating light is standard on the oven so a user or welding inspector can see from a distance that the unit is powered on.

Performance Heating

The custom-designed heating elements used on Keen portable welding rod ovens are part of a new class of highly energy-efficient, technologically-advanced heating elements that have a very low environmental impact.

Weite 1.6mm/2mm Low Melting Point Aluminum Tig Welding Rods Set, No Need Solder Powder (D)

- Aluminum TIG Welding Rods

- Made in USA or Imported

- Great Welding Effect – With full & smooth welding effect because of internal powder. With low melting point(647℃~658℃), great weldability and corrosion resistance, high thermal conductivity, high electric conductivity and excellent processing performance.

- Wide Application – It is mainly used for argon arc welding and filling material for pure aluminum, connection with aluminium bus and guide rod of electrolytic aluminium plant and electric power, chemistry, food and so on.

- No Need Solder Powder – You don’t have to use other flux powder with aluminum alloy as the welding core and coating as the salt base. Very convenient and easy to weld.

- Widely Use In Life – Suitable for welding or surfacing welding alloy with high strength, good forgeability & good corrosion resistance.

- Light Weight & Small Volume -very easy to bend & carry.

Specification:

Material: Aluminum

Color: Silver

Melting Point: 647℃~658℃

Diameter: 1.6mm / 2mm

Length: 500mm / 19.7″

Recommended for welding or brazing aluminum alloy: 1060, 1350, 3003, 3004, 3005, 5005, 5050, 6053, 6061, 6951, 7005, and cast alloys 710.0 and 711.0

How to Use:

Step 1: Clean and polishe the physical surface.

Step 2: Heat the surface of the base material, until the temperature of the wire to the operating temperature of 380℃~400℃, so you can rely on the parent metal heat transfer welding wire to form welds, should not use the flame to burn wire.

Step 3: When repairing thin aluminum, as long as the aluminum base metal heated to the appropriate working temperature, and then use the wire back and forth friction melting to form a weld, only with a metal brush melt welding wire to weld at the weld.

Step 4: Use propane gas to weld s mall object, natural slow cooling after welding.

NOTE:

1. The surface of the base metal must be clean.

2. The base metal temperature to reach 400 degrees, including the process of welding the base metal temperature should be maintained at 400℃, and the temperature can be high or low.

Package List:

10/20 × Aluminum Welding Wire

✅ SUPERIOR SERVICE & 100% MONEY BACK GUARANTEE

Weite provides you a friendly customer service. All your problems will be answered within 12 hours in business days. For any reason, you are not 100% satisfied with our product, just contact us and you will get a full refund! Choose Weite, enjoy every day!

RAPICCA Leather Forge Welding Gloves Heat/Fire Resistant, Mitts for Oven/Grill/Fireplace/Furnace/Stove/Pot Holder/Tig Welder/Mig/BBQ/Animal handling glove with 16 inches Extra Long Sleeve – Blue

- EXTREME HEAT RESISTANT PROTECTION – RAPICCA Leather Welding Gloves are guaranteed to withstand extreme temperatures up to 932°F(500℃) .The inside of the gloves feature a 100% soft sweat absorbent cotton lining for added softness and heat resistance, that makes these gloves ideal for welding,gripping hot stuff such as burning coal or wood & heat oven or cookware.Perfect for handling animal like DOG CAT BIRD REPTILE from getting bited!

- SUPERIOR SECURITY FOR FORERAMS – The 16 inches extra long glove with 7.5 inches long sleeve protect your forearms from grinding debris, welding sparks, hot coals and open flames, hot kitchen ware and hot steam. Effective even in extreme environments.

- Reinforced Double Layered Kevlar Padding on Fingers, Palms& Backs: RAPICCA Blue gloves have Reinforced Kevlar shielding on the Fingers, Palms& Backs, Provide the most extreme heat protection to handle high heat hazard jobs and make them not easy to wear out.

- THICK AND DURABLE – RAPICCA Welding & BBQ gloves are made from carefully-selected thick and soft shoulder split natural cowhide leather which is heat resistant, oil resistant, puncture resistant, fire resistant and cut resistant. This pair of heavy duty gloves will last for a long time.

- MULTI – FUNCTION FOR MEN & WOMEN – They are not only for welding but also useful for many other work and home tasks. Idea for Grill, Barbecue, Stove, Oven, Fireplace, Cooking, Pruning flowers, Gardening, Camping, Campfire.

Welding Rods Copper Aluminum Cored Wire Low Temperature Welding Rod for Radiators Motors Batteries Household Appliances (10M)

- ◉CONVENIENT TO USE: The aluminum cored wire can be used directly without the need for other flux powders.

- ◉EXCELLENT WELDING EFFECT: The aluminum cored wire has excellent welding performance when used, and the welding effect is full and smooth.

- ◉GOOD HARDNESS AND TOUGHNESS: The aluminum cored wire has a low melting point, good hardness and toughness, and has good sealing properties at the position after welding.

- ◉FEATURES: The welding residue of this aluminum cored welding wire is non-corrosive, non-hygroscopic and firmly attached.

- ◉APPLICATION: Suitable for copper and aluminum wire welding of radiators, motors, batteries, household appliances and other products.

Specification:

Condition: Brand New

Length: 1/2/4/10m (Optional)

Package Weight: 28~277g (approx.)

Package List:

1 x Copper Aluminum Cored Wire

Welding Rods Copper Aluminum Flux Cored Wire Welding Rod Low Temperature for Radiators Motors Household Appliances (10M)

- 【EXCELLENT PERFORMANCE】– The melting point of this aluminium-cored wire is low. After welding, the sealing of the welding part is very good.

- 【EASY TO USE】– The aluminum cored wire can be used directly without the need for other flux powders.

- 【NON-CORROSIVE WELDING RESIDUE】– The flux residue of the aluminum cored wire is not corrosive, does not absorb moisture and adheres firmly.

- 【SUITABLE FOR】– This welding rod is widely used for copper and aluminum wire welding of radiators, motors, batteries, household appliances and other products.

- 【EXCELLENT WELDING PERFORMANCE】– The aluminum cored wire has excellent welding performance when used, and the welding effect is full and smooth.

Specification:

Condition: Brand New

Length: 1/2/4/10m (Optional)

Package Weight: 28~277g (approx.)

Package List:

1 x Copper Aluminum Cored Wire

Similar items with 4 stars and above

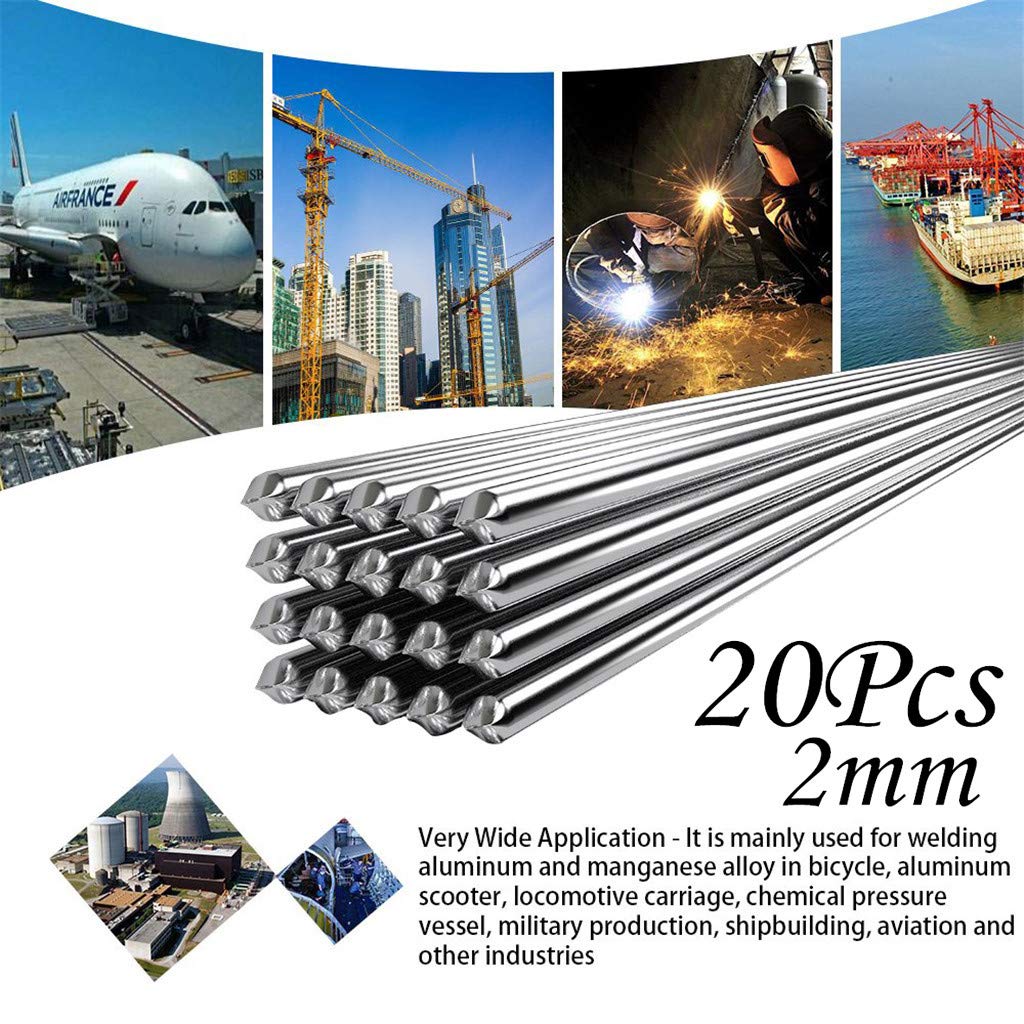

Weite 1.6mm/2mm Low Melting Point Aluminum Tig Welding Rods Wire Cores Set, No Need Solder Powder (20 Pieces)

- Aluminum TIG Welding Rods

- Made in USA or Imported

- Great Welding Effect – With full & smooth welding effect because of internal powder. With low melting point(647℃~658℃), great weldability and corrosion resistance, high thermal conductivity, high electric conductivity and excellent processing performance.

- Wide Application – It is mainly used for argon arc welding and filling material for pure aluminum, connection with aluminium bus and guide rod of electrolytic aluminium plant and electric power, chemistry, food and so on.

- No Need Solder Powder – You don’t have to use other flux powder with aluminum alloy as the welding core and coating as the salt base. Very convenient and easy to weld.

- Widely Use In Life – Suitable for welding or surfacing welding alloy with high strength, good forgeability & good corrosion resistance.

- Light Weight & Small Volume -very easy to bend & carry.

Specification:

Material: Aluminum

Color: Silver

Melting Point: 647℃~658℃

Diameter: 1.6mm

Length: 500mm / 19.7″

Recommended for welding or brazing aluminum alloy: 1060, 1350, 3003, 3004, 3005, 5005, 5050, 6053, 6061, 6951, 7005, and cast alloys 710.0 and 711.0

How to Use:

Step 1: Clean and polishe the physical surface.

Step 2: Heat the surface of the base material, until the temperature of the wire to the operating temperature of 380℃~400℃, so you can rely on the parent metal heat transfer welding wire to form welds, should not use the flame to burn wire.

Step 3: When repairing thin aluminum, as long as the aluminum base metal heated to the appropriate working temperature, and then use the wire back and forth friction melting to form a weld, only with a metal brush melt welding wire to weld at the weld.

Step 4: Use propane gas to weld s mall object, natural slow cooling after welding.

NOTE:

1. The surface of the base metal must be clean.

2. The base metal temperature to reach 400 degrees, including the process of welding the base metal temperature should be maintained at 400℃, and the temperature can be high or low.

Package List:

10/20 × Aluminum Welding Wire

✅ SUPERIOR SERVICE & 100% MONEY BACK GUARANTEE

Weite provides you a friendly customer service. All your problems will be answered within 12 hours in business days. For any reason, you are not 100% satisfied with our product, just contact us and you will get a full refund! Choose Weite, enjoy every day!

Conclusion

By our suggestions above, we hope that you can found welding rod oven used for you.Please don’t forget to share your experience by comment in this post. Thank you!